Below, you’ll find technical data on product specifications, strength testing, assembly instructions, and educational materials. This transparency reflects the quality of Superior Aluminum’s products and processes. Browse the links below or contact us via email or by phone at (937) 526-4065 for assistance.

Superior Aluminum partners with Professional Engineers to ensure railing designs meet building codes. To request a Sealed PE Drawing for your project, contact your Superior Aluminum representative.

How To Measure

Ramp Measurement

Stair Measurement

Assembly Instructions

Before performing any work, be sure to refer to and follow all standard industry safety precautions. In addition, Superior Aluminum Products, Inc. recommends that all installers wear appropriate protective items, such as safety glasses, work gloves, and steel-toed shoes.

- Aluminum Column Assembly Instructions

- Fiberglass Column Assembly Instructions

- Panel Column Insert Instructions

- Aluminum Pipe Cable Railing Assembly Instructions (5C)

- Pipe Railing Assembly Instructions (5H/5P)

- Level Railing Kit Assembly Instructions (6E)

- Step Railing Kit Assembly Instructions (6E)

- Level Fence Assembly Instructions (Series 7)

- Field Assembly of Series 9P Railing

- Step Railing Kit Assembly Instructions (9P)

- Level Railing Kit Assembly Instructions (9P)

- Aluminum Cable Railing Assembly Instructions (9C)

Product Specifications

The following documents have been developed by Superior Aluminum to assist Architects and Designers in the specification of aluminum railing products.

- Series 9P – Picket Railing Specification (PDF)

- Series 9C – Cable Railing Specification (PDF)

- Series 5H – Non-Welded Aluminum Pipe Railing Specification (PDF)

- Series 5P – Non-Welded Pipe Picket Railing Specification (PDF)

- Series 5C – Pipe Cable Railing Specification (PDF)

- Series 9H – Horizontal Railing Specification (PDF)

- Series 9M – Mesh Railing Specification (PDF)

- Series 9G – Glass Railing Specification (PDF)

- Series 7V – Aluminum Privacy Fence Specification (PDF)

Material Specifications

Series 9P, 9H, 7P, 7V, 6E

All rails, posts, and pickets shall be formed from 6063-T5, 6063-T52, 6063-T6, or 6005A-T61 extruded aluminum alloys depending on exact application. All post reinforcement rods (where applicable) shall be formed from 6061-T6 extruded aluminum alloy. All railing accessories shall be cast from industry standard aluminum alloys according to the requirements of the application. All exposed fasteners used in the system shall be aluminum or stainless steel. All PPG Duracron paint finishes and anodized finishes adhere to the specifications set forth by the American Architectural Manufacturers Association.

Series 5H, 5P

All rails and posts shall be formed from 6063-T6 extruded aluminum alloy, except where there are formed elbows, whereby 6063-T4 is used. All pickets shall be formed from 6063-T6 extruded aluminum alloy. All post reinforcement rods shall be formed from 6061-T6 extruded aluminum alloy. All railing accessories shall be cast from industry standard aluminum alloys according to the requirements of the application. All PPG Duracron paint finishes and anodized finishes adhere to the specifications set forth by the American Architectural Manufacturers Association.

Series 9C

All rails and posts shall be formed from 6063-T6 or 6005A-T61 extruded aluminum alloys depending on exact application. All cable shall be 3/16” 1×19 Type 316 stainless steel. All railing accessories shall be cast from industry standard aluminum alloys according to the requirements of the application. All metal cable fittings shall be stainless steel. All exposed fasteners used in the system shall be aluminum or stainless steel. All PPG Duracron paint finishes and anodized finishes adhere to the specifications set forth by the American Architectural Manufacturers Association.

Series 5C

All rails and posts shall be formed from 6063-T6 extruded aluminum alloys, except where there are formed elbows, whereby 6063-T4 is used. All cable shall be 3/16” 1×19 Type 316 stainless steel. All post reinforcement rods shall be formed from 6005-T5 extruded aluminum alloy. All railing accessories shall be cast from industry standard aluminum alloys according to the requirements of the application. All metal cable fittings shall be stainless steel. All exposed fasteners used in the system shall be aluminum or stainless steel. All PPG Duracron paint finishes and anodized finishes adhere to the specifications set forth by the American Architectural Manufacturers Association.

Series 9M

All rails, posts, and infill frames shall be formed from 6063-T6 or 6005A-T61 extruded aluminum alloys depending on exact application. Wire Mesh infill shall be formed from 1350-H18 aluminum alloy. Perforated Panels shall be formed from 3003-H14 aluminum sheet. All railing accessories shall be cast from industry standard aluminum alloys according to the requirements of the application. All exposed fasteners used in the system shall be aluminum or stainless steel. All PPG Duracron paint finishes and anodized finishes adhere to the specifications set forth by the American Architectural Manufacturers Association.

Series 9G

All rails and posts shall be formed from 6005A-T61 extruded aluminum alloy. Glass shall be clear, laminated and tempered, with EVA innerlayer unless otherwise specified. All railing accessories shall be cast from industry standard aluminum alloys according to the requirements of the application. All exposed fasteners used in the system shall be aluminum or stainless steel. All PPG Duracron paint finishes and anodized finishes adhere to the specifications set forth by the American Architectural Manufacturers Association.

Aluminum Columns

All columns shall be formed from 6063-T5 aluminum alloys. All column accessories shall be cast or extruded from industry standard aluminum alloys according to the requirements of the application. Polymer accessories shall be cast from high-density urethane composite. All PPG Duracron paint finishes and anodized finishes adhere to the specifications set forth by the American Architectural Manufacturers Association.

Fiberglass Columns

All columns shall be formed from fiberglass-reinforced polymers. All column accessories shall be formed from fiberglass-reinforced polymers or lightweight polyurethane.

PVC Columns

All columns shall be formed from cellular PVC.

Colors & Finishes

*What is Satin Anodized?

Anodizing is an electrochemical process that converts the metal surface of aluminum into durable, corrosion-resistant, anodic oxide finish. Please note that deviations are common among similar alloys with even greater deviations occurring among different alloys.

Do PVC Column Wraps require special paint?

All Superior PVC Column Wraps come in a standard white finish that does not require painting. If painting is desired, it is recommended that 100% acrylic paint with or without a urethane additive is used. Additionally, it is recommended that a light reflective value (LRV) of 55 units or greater is chosen.

Do your finishes adhere to any standards or codes?

Yes, all standard finishes offered by Superior adhere to the provisions set forth by the American Architectural Manufacturer’s Association.

What type of paint is used on Superior’s standard color options?

Extruded pieces (top/bottom rail, posts, pickets, etc.) are painted with PPG Duracron paint, while castings (brackets, caps, bases, etc.) are powder coated.

What type of Anodized finish is standard?

The standard Satin Anodized finish for all railing is 15M Clear Anodized, Aluminum Association Designation AA-M12-C22-A21, which has a minimum coating thickness of .15mils. Series 500 and 550 have two additional anodized options: A 60M Clear Anodized, Architectural Class 1 finish, with the designation AA-M12-C22-A41, and a 60M Brushed Anodized, Architectural Class 1 finish, with the designation AA-M35-C22-A41, both with minimum coating thicknesses of .7mils. Any Anodized railing outside of the standard 15M Clear Anodized finish may be subject to additional costs.

What coating thicknesses are your standard finishes applied to?

The minimum thickness specifications include .8mils for painted finishes and.15mils for anodized finishes. Actual thicknesses typically exceed these figures.

Are any products available in Duranodic finishes?

Yes: Duranodic coatings can be applied to any of our products at an additional fee. Colors available range from Champagne to Black.

Are custom finishes available?

Yes: Any of our products can be custom painted with a special color or high performance paint at an additional fee.

What if I would like to paint your products myself?

All of our products are available in a mill finish if painting or chemical treating by a 3rd party is preferred. However, Superior does not recommend that any of its products be installed permanently without adequate surface protection.

Frequently Asked Questions

Aluminum Railing

Does aluminum railing rust?

Aluminum is a popular metal for railing because of its rust-resistant properties. Most other railing materials will corrode, rust, or warp over time. The strength and durability of an aluminum railing makes it an attractive option for any outdoor application.

What are the benefits of aluminum railing?

Aluminum is arguably the preferred material for outdoor railing applications because of its durability and low-maintenance care. To read more about how aluminum stacks up against other materials, click here to read a post from the Superior blog regarding this debate.

How long do aluminum railings last?

One of the most important properties of aluminum railing is its durability. An aluminum railing system can last decades with little maintenance required. Other railing materials may require frequent re-painting, coating, cleaning, and ultimately a full replacement system.

When is a railing required on a porch?

Depending on the installation location of your railing, different height restrictions apply. Residential locations (where railing is generally installed closer to the ground) such as a home only require railings to be 36” high (and only is required by code if the drop is over 30”). In a commercial application such as an apartment building or hotel, code requirements state that a railing should be at least 42” high. These measurements are to be taken from the ground to the top of the railing.

For more information on railing building code, read our article “Do You Know Your Code?”

Of course, some people simply prefer the aesthetic of railing on a porch even if it’s not required!

How much do aluminum railings cost?

Each Superior Aluminum railing is customized to meet the exact specifications of your project. This means no two jobs are the same, and you get exactly what you need. Our lowest cost railing system is Series 6E, while Series 9P is our most popular square picket railing for residential and commercial applications as well as having a medium price point. For a premium aesthetic and product, Series 9C and 9M will elevate your look but carry the highest price points.

For more information on pricing and materials, please submit a quote at https://superioraluminum.com/get-a-quote/

Aluminum Columns

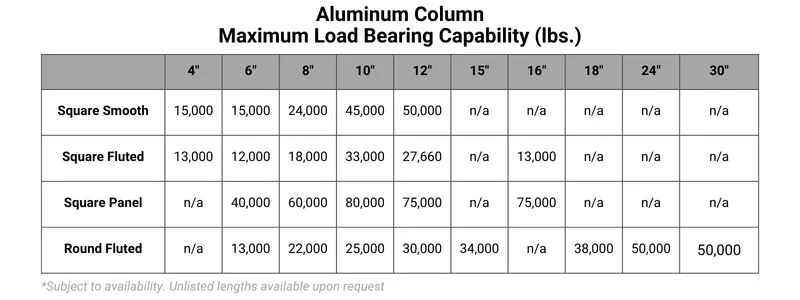

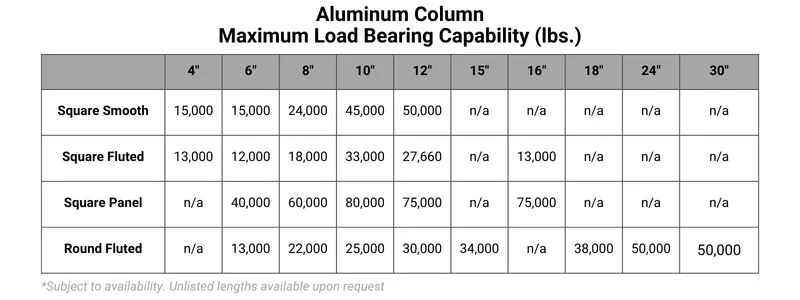

Are aluminum columns load-bearing?

Yes, most Superior Aluminum columns are load-bearing. Reference the table below for information on maximum load-bearing capabilities for each aluminum column style.

How much weight can an aluminum column hold?

Load-bearing capabilities vary by style and size of the column. For more information on maximum load-bearing capabilities, reference the table below.

Can you paint aluminum columns?

All of Superior’s aluminum product lines are available in a mill finish if painting or chemical treatment by a 3rd party is preferred. However, Superior does not recommend that any of its products be installed permanently without adequate surface protection.

How do you clean aluminum porch columns?

For basic cleaning, Superior’s aluminum products can be cleaned with warm, soapy water to remove dirt and debris from the product. For more intense cleaning, a 1:1 vinegar/hot water mix can help clean and shine your metal. Regular cleaning of the product is suggested to keep your aluminum products in good condition and ensure the durability of the product.

Click here to read our full cleaning and maintenance guide.

Can aluminum columns be set in concrete?

Aluminum columns can be secured to your surface using standard construction practices. L-brackets are a commonly used method to secure your column to the concrete surface.

How to install aluminum columns?

Click here to read our Aluminum Column Assembly and Installation Instructions.

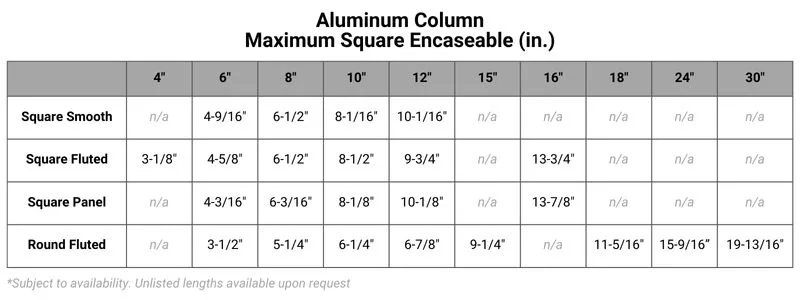

Can you wrap aluminum columns around existing structures?

Yes, almost all aluminum column sizes and styles are available with wrap-around functionality. 4” square smooth columns are not available with wrap-around functionality. For more information on maximum encaseable sizing, please reference the chart below.

Can aluminum columns be cut down?

Aluminum columns can be cut down to size. A chop saw with a metal/carbide tipped blade is ideal for cutting columns down to size. It is recommended that columns be cut slightly smaller than the height of the install area in order to more easily fit.

Click here to view Aluminum Column Assembly and Installation Instructions.

What type of paint is used on aluminum columns?

PPG Duracron paint is used to paint Superior’s aluminum columns and caps and bases. Duracron extrusion coatings meet AAMA 2603 specifications and offer good film integrity, color control, and weather resistance. They must be factory applied to properly cleaned and pretreated aluminum for optimum performance.

What type of primer and paint should be used if painting Mill?

A multi-purpose primer that is specially designed for metal should be used to prime your column. This information can be found on the “applications” section on the label of the paint.

Please make sure your surface is clean, dry, and dull before applying primer. The surface of the product should be prepared in alignment with the recommendations of the chosen coating manufacturer to ensure proper adhesion.

Superior does not recommend that any products are installed permanently without adequate surface protection. We encourage you to talk to your local paint store expert or a professional painter to recommend a proper combination based on your particular environment, preferences, and application.

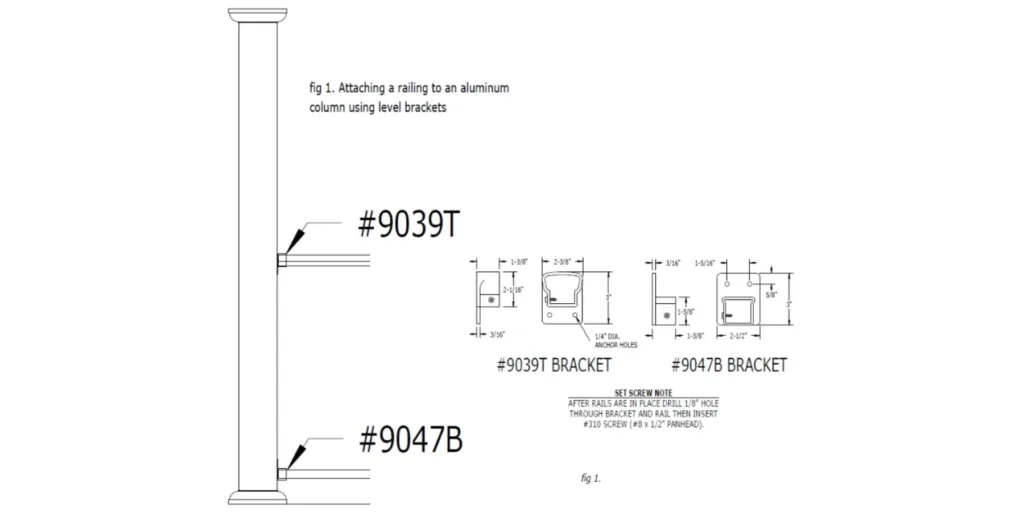

Can I attach railing to aluminum columns?

Yes, your aluminum railing can be attached to your column via Superior Aluminum brackets. Most commonly used are level brackets but vertical or horizontal swivels are available as well. Round Superior Aluminum columns have an option to include an adaptor to create a flat surface.

Please note Superior will generally not provide anchors for attaching these brackets to the column. At this time, premium railing options are not able to attach to columns with this system.

Where can I buy aluminum columns?

Visit our online store at BuyMBS.com for online ordering of aluminum columns, PVC columns, caps, bases, and accessories. To find a local store or lumber yard that can order Superior Aluminum columns, visit our “Find a Location” page.

PVC Columns

Can I paint PVC Columns?

All PVC Column Wraps come in a standard white finish. This finish is weather resistant, so no painting is required. However, all PVC Column Wraps can be painted with 100% acrylic exterior paint or acrylic with urethane additive paint. Paint should feature a Light Reflective Value (LRV) of greater than 55. At this time painting does void the warranty.

What size PVC column do I need?

For Snap-Tite PVC® columns, a 6” column wraps a 4×4 post, and an 8” column wraps a 6×6 post. This product is available in 8’ or 10’ lengths.

How do I install PVC Columns?

Click here to view complete Snap-Tite PVC column installation instructions

How do I anchor PVC columns?

Be sure to secure your PVC column at both the capital and the base, according to standard construction practices, using one of the prescribed methods below.

Method A: L-brackets are a commonly used method (sold separately).

Method B: Screw directly into the treated wood post (if the column is within 1/4” centered).

Method C: For a Post Jack, add four treated blocks (two top and two bottom) around jack to drill screw into. Size of blocks are dependent on area between column ID and Post Jack. When drilling, for cement use Tapcon screws, for wood use wood screws.

Do I need spacers on my existing columns?

While not a requirement, spacers will alleviate potential weakness along the long portions of the column. Some installers will choose to use spacers on all four sides, while others will use spacers on one side while securing columns to load support on one side.

Are PVC columns load bearing?

PVC are wrap-around only, and should not be used in load-bearing applications.

Do I need to glue Snap-Tite® columns?

Superior’s Snap-Tite® PVC Column Wraps use a patented design that is the industry’s first and only column wrap that does not require PVC Glue or other adhesives. Simply snap together the columns and enjoy your new Snap-Tite® PVC Column Wrap.

Can I attach railing to PVC Columns?

Yes, your railing can be attached to your PVC column. However, proper blocking will need to be installed on the support column to ensure a strong connection.

Where can I buy PVC columns?

Visit our online store at BuyMBS.com for online ordering of aluminum columns, PVC columns, caps and bases, and accessories. To find a local store or lumber yard that can order Superior aluminum columns, visit our “Find a Location” page.

For large orders or bulk pricing, please contact us for more information.

Fiberglass Columns

What type of primer and paint should be used if painting Fiberglass?

High-end acrylic primers and paints should be used to paint fiberglass columns in exterior applications. Latex paint and primers may be best suited for interior applications. For additional support, we encourage you to talk to your local paint store expert or a professional painter to recommend a proper combination based on your particular environment, preferences, and application.