As is common with almost all aspects of the construction industry, aluminum railing on a project must meet a specific set of code requirements set by the International Code Council. Today we are going to look at a couple of those requirements and look at why such restrictions are in place. The full listing of these and other railing codes can be found in section 1015 of the International Building Code. Learn more about the code council and building codes, as well as other aluminum railing info here.

Disclaimer: All code discussed in this article is national code. Some states/cities/townships may have more specific code requirements which trump the national code. Always be aware of special requirements in your project area.

RAILING HEIGHT

Depending on the installation location of your railing, different height restrictions apply. Residential locations (where railing is generally installed closer to the ground) such as a home only require railings to be 36” high. In a commercial application such as an apartment building or hotel, code requirements state that a railing should be at least 42” high. These measurements are to be taken from the ground to the top of the railing.

PICKET SPACING

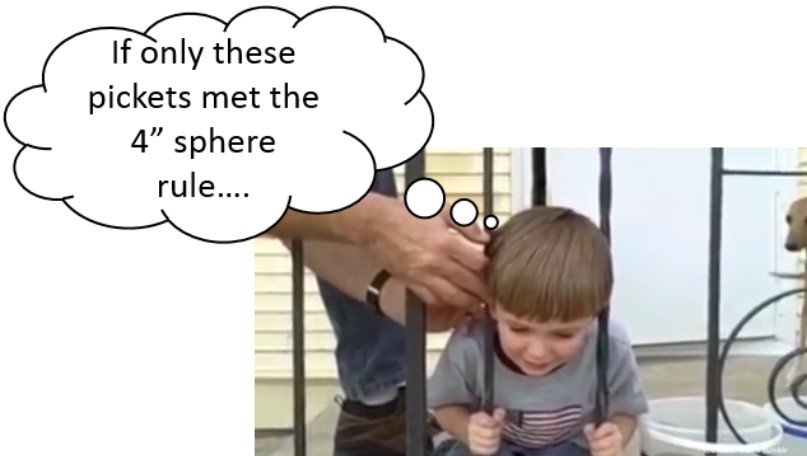

Believe it or not, the space between pickets, sometimes referred to as balusters, in a railing system (or horizontal components) is restricted by the national building codes. In most cases, pickets or horizontal components (such as cables or pipe) must be spaced that a sphere 4” in diameter will not be able to pass through. Some in the industry refer to this as “passing the sphere test.”

In terms of why this is the rule, we could explain it to you but sometimes a picture really is worth a thousand words:

That’s right, 4” was not just an arbitrary number but rather a carefully calculated size to keep curious children from getting stuck!

One important note to keep in mind when designing your railing system is that some more exclusively adult locations have lighter restrictions. The main example of this is a railing in an industrial setting, such as a walkway to electrical systems or a barrier to mechanical systems, only needs to prevent the passage of a 21” sphere. Much more forgiving to compensate for the more mature users of the system.

WHAT ABOUT THE REST?

There are multiple other code requirements involved in creating the perfect aluminum railing system, however those are for another day. At Superior Aluminum, safety is a top priority so we ensure that each railing system that leaves our facility meets all code requirements, even beyond those discussed here. If you have more in-depth questions about railing codes or would like to learn more about how Superior Aluminum meets code requirements, feel free to contact us. Stay tuned for more building code tips in the future!